March 2, 2016

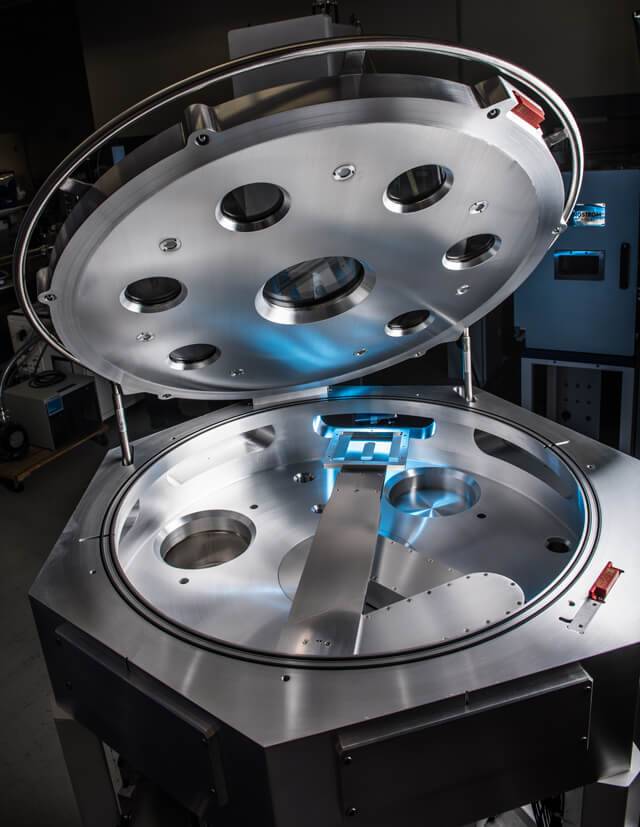

When one of our Nebula cluster tools is out on the shop floor, it dominates everyone’s attention. These impressive systems feature multiple chambers that adhere to our partners specific requirements. They can include any type of physical vapor deposition (PVD) source, chemical vapor deposition (CVD), atomic layer deposition (ALD), ion beam etching, substrate cleaning and encapsulation. All manner of stage options (like heating, cooling, biasing, and glancing angle) are available, and these cluster tools always have a fun array of substrate transfer, automatic mask exchange chambers, and robotic capabilities.

The custom software that we developed for the complicated recipes that can simultaneously run in this cluster is part of what sets it apart. Auto-tuning PID, multiple source deposition control, fully integrated temperature and motion control make the Nebula cluster a piece of scientific engineering we’re proud of.

“I am excited about offering the Nebula system to our partners,” says Angstrom Engineering President Dave Pitts, “it will further enhance their capabilities to produce truly world class results. The accuracy and flexibility of the system will increase the complexity of the devices that can be created while also increasing the repeatability of the results and the throughput with which they are created.”

The potential of these systems gets us excited about the incredible breakthroughs in science and technology that we will get to play a part in.

We call the robot on this cluster Steve. Steve is precise, consistent, reliable and nearly maintenance free.