Linear Sputter PVD System

This series of Linear Sputter PVD systems allows for high throughput production on large substrates, can be seamlessly integrated into larger clusters of production tools, and provides impressive uniformity.

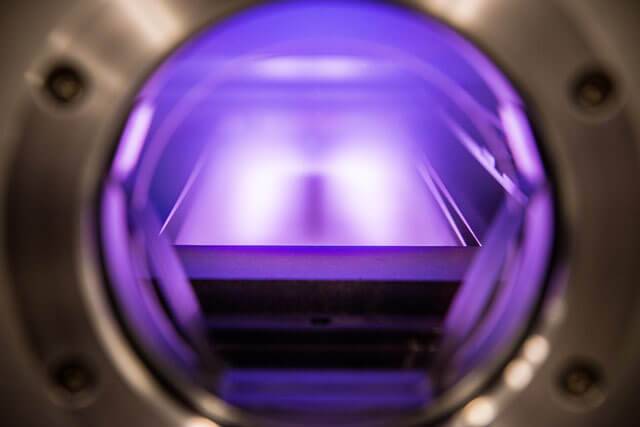

Using the Linear Sputter PVD system from Angstrom Engineering allows you to process thin films of semiconductors or metals on large area panels in display, photovoltaic, and semiconductor applications. We designed these systems to address the challenges researchers face when sputtering over large areas or quantities of substrates. From gas flow and plasma management to magnetron uniformity and temperature control, Angstrom’s Linear Sputter PVD systems let you revolutionize your workflow and see higher throughput production than previously possible.

Create devices on very large substrates, stacking multiple layers in a single run with great uniformity. Even though the targets are larger than usual, the material is very efficiently utilized.

The tool to bring your product to market

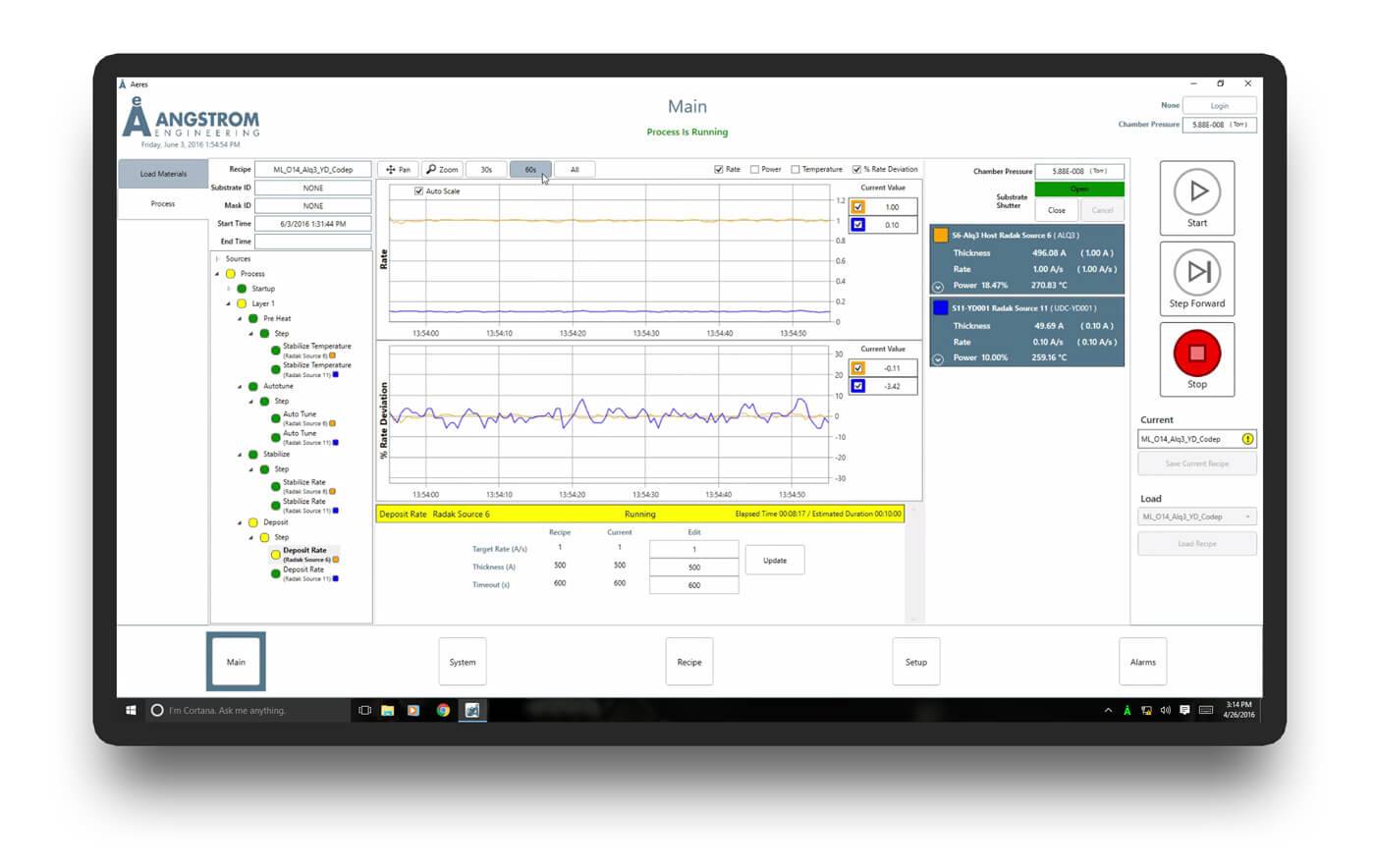

Aeres® Advanced Process Control Software

WE WANT TO HEAR ABOUT YOUR PROCESS!

Please get in touch and we can collaborate on your project

When we work together, amazing things can happen. Your brilliant ideas with our innovative team will create the tool that will bring your research or production to the next level. We’re looking forward to hearing from you: