Optical Monitoring & Control

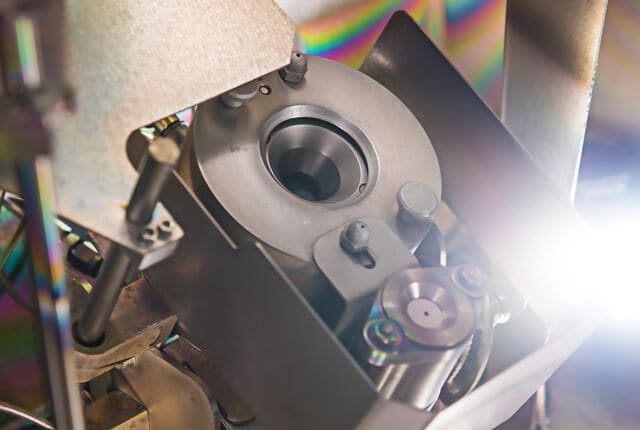

An integrated package that can be used with many of our PVD platforms makes optical monitoring and controlling a seamless process.

From recipe creation, to the final production of the film, this package provides complete and simple control of your optical films. 30 witness discs are stored in an automatic chip changer for constant data feedback, and you can confirm your films with a PC controlled monochromator that can generate 350-2500 nanometer wavelengths.

A powerful tool that unifies all aspects of optical monitoring and deposition control.

Learn more about different optical coatings categories.

Introduction

Antireflection Coatings

Optical Filters

Beam Splitters

Every component necessary for optical perfection —

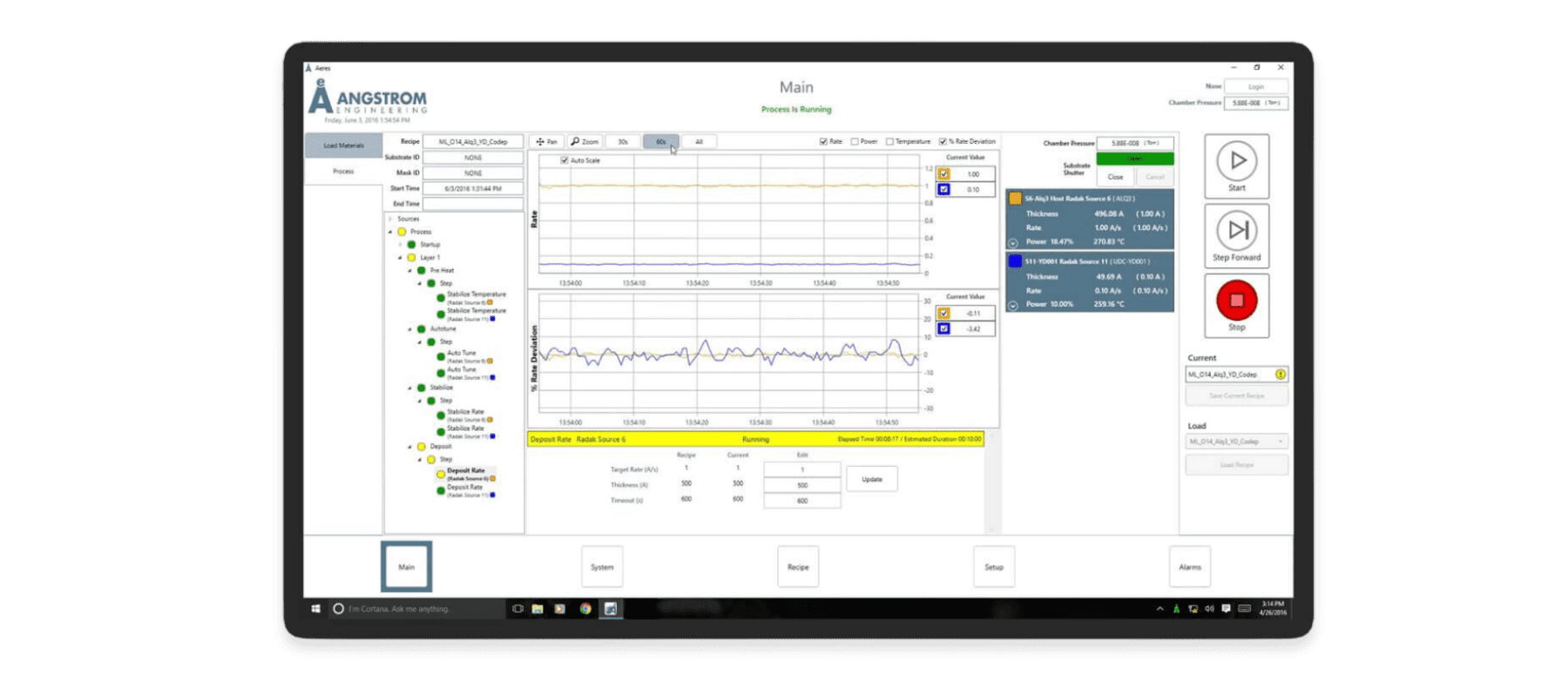

Advanced Process Control Software

- PC/PLC-controlled recipes for single, batch, or automated processes.

- Advanced data logging and process tracking ensure consistent and repeatable processes.

- High-resolution control provides impressive low-rate stability and consistent doping ratios.

- The central control station manages each module and schedules the processes in each chamber.

- Independent control of multiple chambers (if applicable).

- Complex recipes can be created and modified easily.

- Automatic PID control loop tuning significantly reduces process development time.