Mask Handling

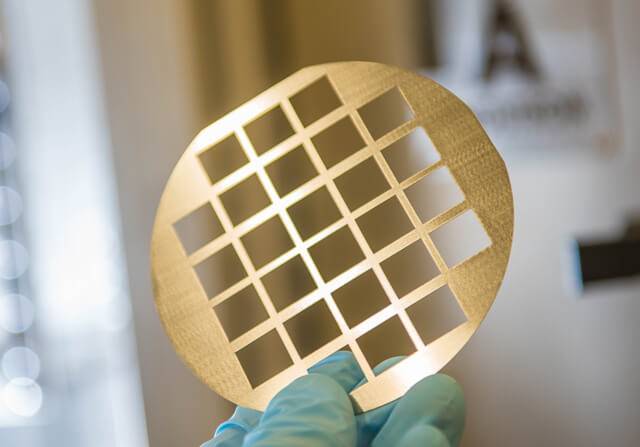

A shadow mask simply stops material from being deposited onto a sample in a desired pattern overlay, creating a ‘shadow’ area on the substrate on which no material is deposited. Many times, in order to achieve the desired device architecture, a single sample will require the use of multiple masks over several deposition runs.

Our automated systems allow for this, along with the management of recipes involving multiple sample and mask combinations.

Angstrom Engineering’s approach is designed to provide the smallest possible feature size (micron scale) while maintaining excellent alignment accuracy and precision. This precise substrate and mask management is complemented by a robust and proven automated robotic handling architecture which maximizes system throughput while eliminating the likelihood of dropped, damaged, or misaligned substrates.

The automation is designed to reduce operating times and cost while effectively increasing the throughput without compromising the quality of the deposited materials. Automated control allows the user to perform multiple deposition runs without exposing the materials or process module to atmosphere time and again, which increases the quality and repeatability of the fabricated films and devices thereof, especially in case of organic electronics.

Substrate carriers and mask frames can be stored in a variety of positions, including isolated parking load locks or deposition module-integrated parking stations. To create a substrate/mask stack, the handler first picks up a mask frame followed by a substrate carrier; to separate the substrate from the mask, the stack must be placed into specific levels of a parking cell which contain dedicated, tapered separator pins. The tapered pins take advantage of dissimilar sized separator through-holes on the substrate carrier and mask frame; dropping the substrate/mask stack onto the tapered pins creates enough separation for the handler to individually pick and place the parts into their next logical position. Storing mask frames within a deposition module-integrated parking station allows in-process mask changing without ever removing the mask or substrate from the deposition vacuum environment.

This video demonstrates how mask handling capabilities come naturally to us.

This short video demonstrates automated mask/sample exchange.

One mask or many? We can handle it.

Let’s Talk about it.

We look forward to discussing this with you.

We are exceptionally pleased with the two systems we bought from Angstrom and, based on our experience and what I hear from the community, we have made precisely the best decision.

Dr. Luke Brzozowski –

University of Toronto