Aeres®

With 25 years of experience helping our partners achieve their process requirements, we created Aeres®, a software platform that solves many known limits in thin film deposition technology. When Aeres® is partnered with one of our PVD platforms, you have an intelligent tool that will save you a lot of time, effort, and resources.

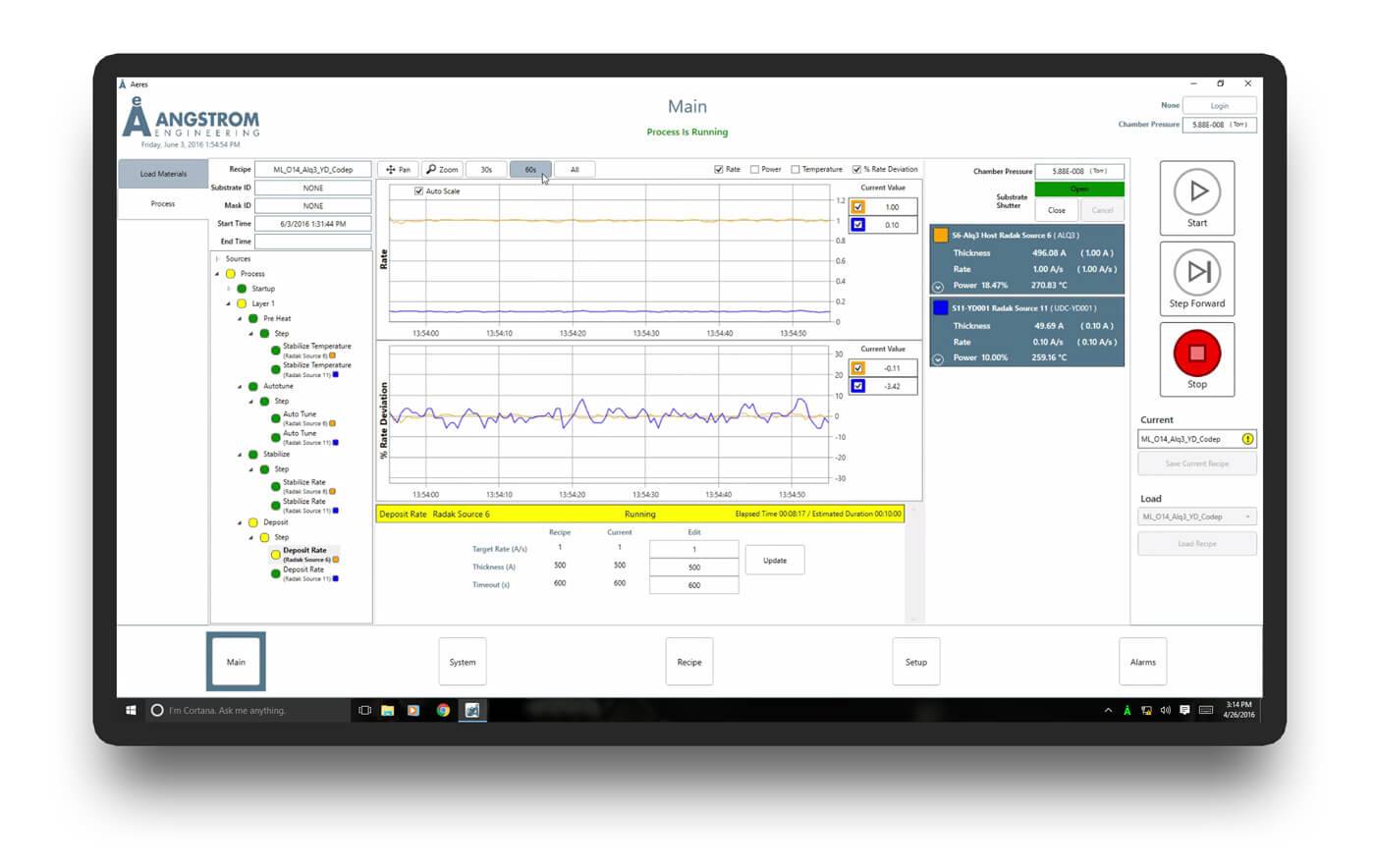

Powerful enough for the most advanced user and complex recipes. Simple enough for every user in the lab

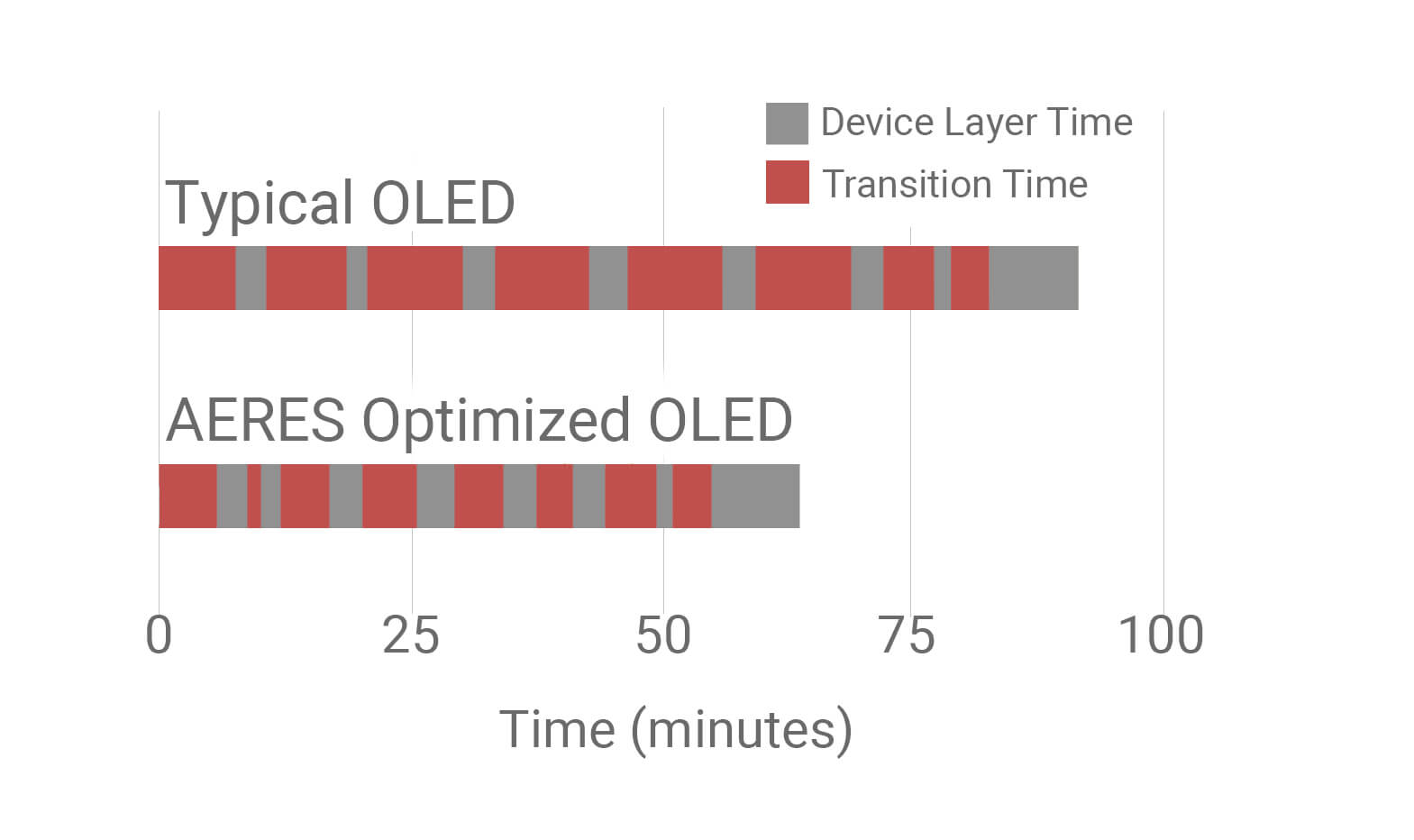

Layer Transition Efficiency

Recipe Control

Every aspect of your process; One Unified Recipe

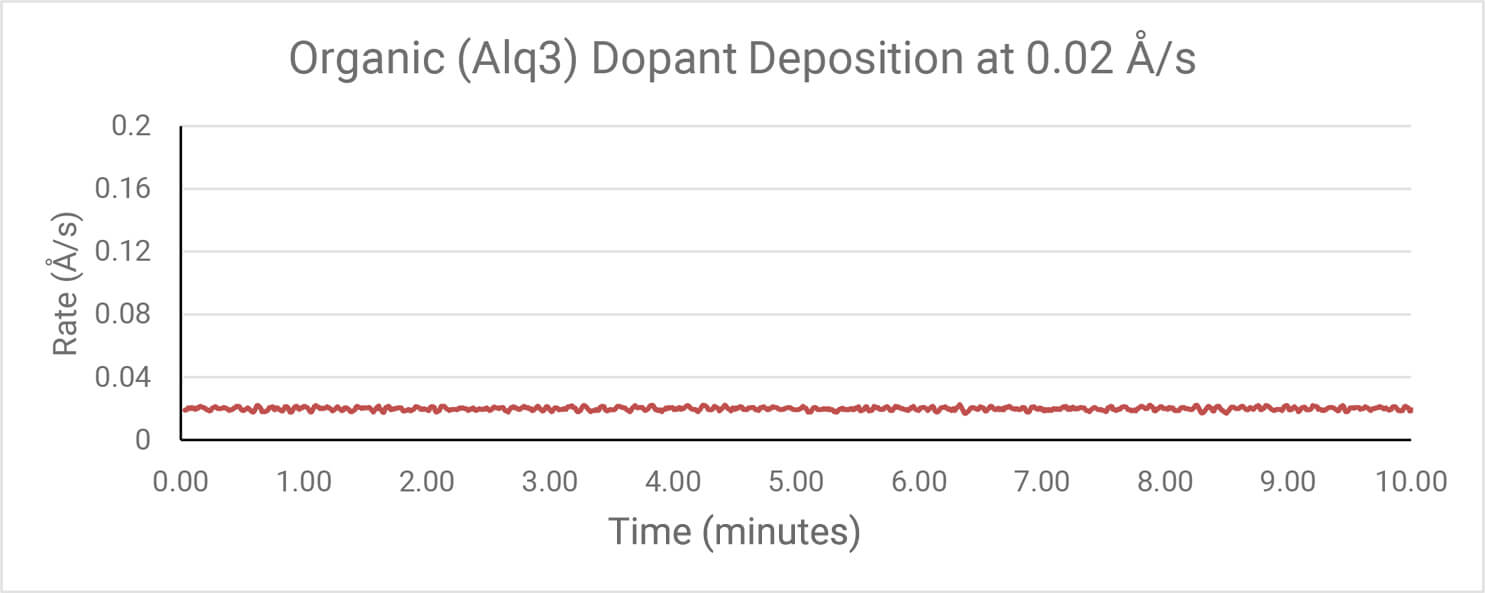

Advanced Deposition Control

Above: Actual stability while depositing a common OLED material (Alq3) at 0.02 Angstroms per second

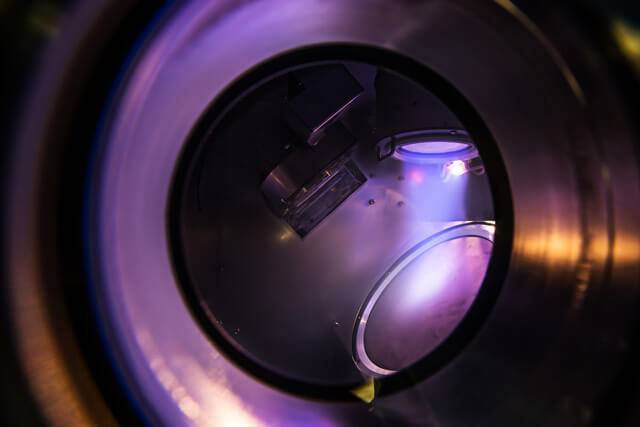

Aeres® enhances your Equipment

All its features come standard

Discover More...

Aeres® takes care of some very sophisticated automation capabilities. Click the links below to find out more.

WE WANT TO SHOW YOU A LIVE VERSION OF AERES®!

Please get in touch and we can personally go over its features with you via a live demo.

When we work together, amazing things can happen. Your brilliant ideas with our innovative team will create the tool that will bring your research or production to the next level. We are looking forward to hearing from you:

The level of service and connectivity to their customers, answering your emails any time of day, and helping you trouble shoot from afar is above and beyond what I had ever seen before. That interaction is what has made me a die-hard customer from here on out.

Dr. Casey Smith - Texas State University