August 16, 2018

The team of PhDs at Angstrom Engineering takes pride in seeing how their recommendations help our partners in research do the heavy intellectual lifting needed to publish high-impact articles, because they know precisely what it takes to leverage knowledge into results at this level. A recent paper by the research teams at Argonne National Laboratory and the Departments of Physics and of Materials Science and Engineering at Drexel University highlights how Angstrom’s ion-beam-assisted sputtering (IBAS) systems can provide researchers with a flexible solution for precise control over film stoichiometries and morphologies. It presents an intriguing technique for synthesizing superconducting niobium nitride (NbN) thin films at ambient temperatures.

For anyone looking to deposit thin films, process conditions at the substrate can have a substantial effect on the quality of films, with effects on properties as diverse as stoichiometry, grain structure, oxidation state, material phases present, electrical conductivity, film adhesion, density, and optical transmission. The mobility/kinetic energy of deposited and incident atoms and ions at the surface is primarily responsible for determining the final state of these properties.

Ion-beam-assisted sputtering (IBAS) in magnetron sputtering is gaining popularity because it avoids the common challenges associated with the approaches above, thanks to the mechanism by which energy and mass is transferred from the ion beam to the substrate. By directing a broad beam of current-neutralized ions with a range of ion energies towards the substrate and through a magnetron-sputtered deposition stream, the ions and electrons impart energy to both the substrate surface atoms and incident sputtered atoms.

Films resulting from IBAS have been shown to have greater film densities, increased percentages of certain material phases when compared to other deposition techniques, fewer film voids, and superior film adhesion. Moreover, when the ion beam is complementary to the sputtered material, stoichiometric films can be deposited, all at ambient temperatures with minimal substrate heating from ion bombardment.

Breaking new ground with their recently purchased Angstrom Engineering system, researchers Tomas Polakovic et al. were able to use IBAS to synthesize nearly stoichiometric films of single-phase NbN at ambient temperatures—a significant improvement over the typical 500 °C or more required by other methods. The team was able to find an optimal ion energy for their process, and when comparing the IBAS NbN films with those from a comparable reactive sputtering deposition with no ion-beam assist, they found the IBAS NbN film was far less sensitive to nitrogen concentrations in the system and exhibited superconductivity at superior critical temperatures to those of the reactively-sputtered films.

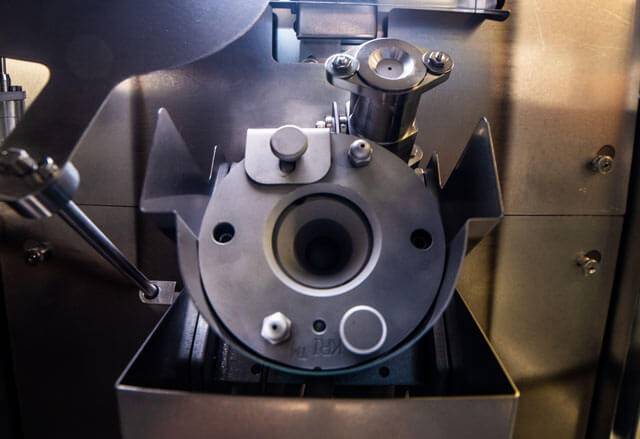

All of this was done in the same system: an Angstrom Engineering UHV Evovac, equipped with both turbo-molecular and cryogenic pumps, a six-pocket electron beam source, 4 sputter sources, an end-Hall hollow cathode ion source (seen left), a variable angle stage, and a load lock with multiple parking stations.

You can read more about our partners’ results here.

We wish to congratulate the teams at Argonne and Drexel on their new publication and the development of their new NbN synthesis method.

This piece was written by Dr. Martin Lennox, a member of Angstrom Engineering's Test & Process Engineering Team.