Angstrom Engineering | Thin Film for Optics and Photonics

You create the future. We’ll handle logisticsTM

Angstrom Engineering engineers and manufactures state-of-the-art vacuum deposition equipment designed specifically to meet the demands of those working towards optical engineering and photonics applications. These systems are well thought out, easy to use, and are unequivocally supported by our team. Reticle is a turn-key system that utilizes ion beam sputter deposition (IBSD) for incredibly pure, dense, and repeatable optical films. Our optical monitoring & control package can be integrated into our physical deposition (PVD) platforms to aid in the creation of your films. An Angstrom system in your lab allows you and your team to focus on the work without worrying about your equipment.

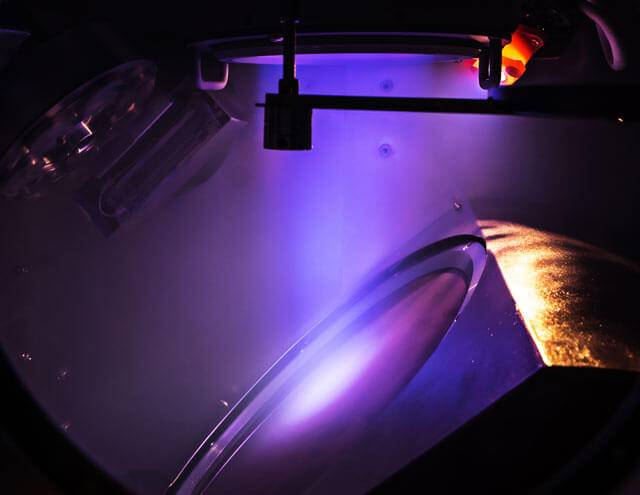

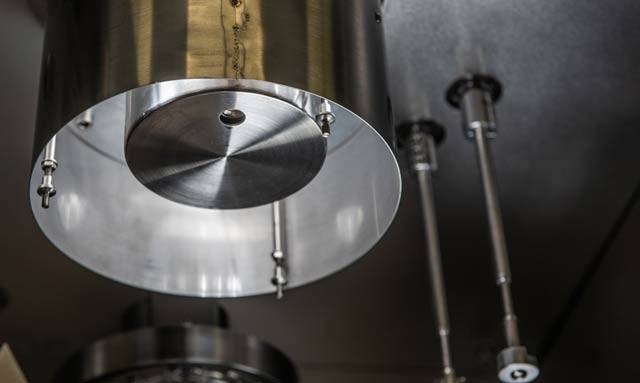

When precision is paramount, reticle delivers

Angstrom has engineered a platform that provides the optics community the ability to create films with excellent purity, density, and uniformity, all in a highly repeatable and automated fashion. This is an ideal system for applications such as antireflective (AR) coatings, highly reflective (HR) coatings, coatings for laser diode bars, telecom optical filters, as well as vanadium oxide deposition. Angstrom Engineering can also provide the capability of in situ ellipsometric measurements for precise control of film thickness and end-point detection.

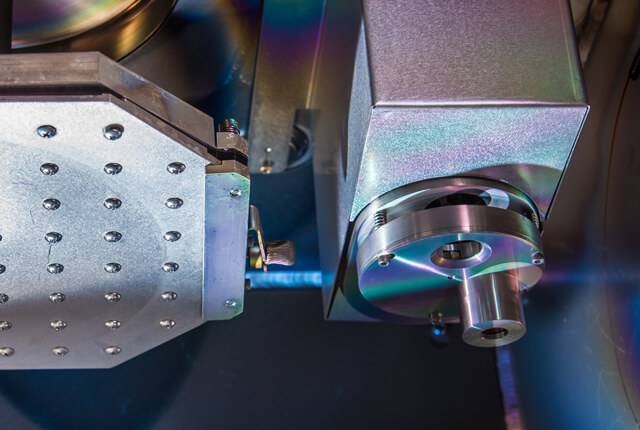

Optical Monitoring & Control: A powerful tool that unifies all aspects of optical monitoring and deposition control

This is a compreshensive package of hardware and software that is integrated into our physical vapor deposition (PVD) system. It includes the means to both simply control, and monitor the creation of precise optical thin films. From witness chip management for constant data feedback, to a PC controlled monochromator that can generate 350-2500 nanometer wavelengths, this package can do it all. All elements combined, it provides a powerful means of creating reliably precise optical films.

From the time it was delivered, this laboratory system has performed nearly flawlessly, arguably extending our capabilities well beyond those currently attainable by any organic thin film laboratory in the world. I attribute the success of this entire system to the excellence of the engineering as well as the cooperative nature of the Angstrom team in taking our best designs and making them better during the system construction process.

Dr. Stephen Forrest – University of Michigan

The EvoVac design is terrific and the glovebox port is easy to work with. Last year, it was used 2269 hours, averaging over 6 hours a day every day of the year. It is the single most used piece of equipment at our facility, and essential to numerous research projects. As such, it is critical that downtime is minimized. The support Angstrom Engineering provides for service issues is exceptional, and unparalleled. My job would be significantly easier if I received the customer support Angstrom offers for the other instruments in our facility.

Dr. Ina Martin – Case Western University