Antireflection Coatings

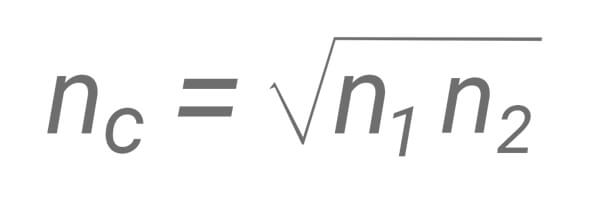

Antireflection coatings minimize the reflection of one or many wavelengths and are typically used on the surface of lenses so that less light is lost. A simple coating can be designed to minimize the reflection on an interface between two materials by providing an extra material for light to interact with. This can reduce the total reflection coefficient of the system by having light reflect from two interfaces where each interface has a smaller difference in refraction indices than the original interface. This type of coating is an antireflection coating, and the optimum refractive index of the coating (nc) to minimize the total reflection coefficient is given by the geometric mean of the two materials that made up the original interface:

In the case of air and glass, the optimum antireflective coating would have a refractive index of approximately 1.23. No real material has this ideal index, but magnesium fluoride (MgF2) is often used because its refractive index of 1.38 comes closest to the ideal value.

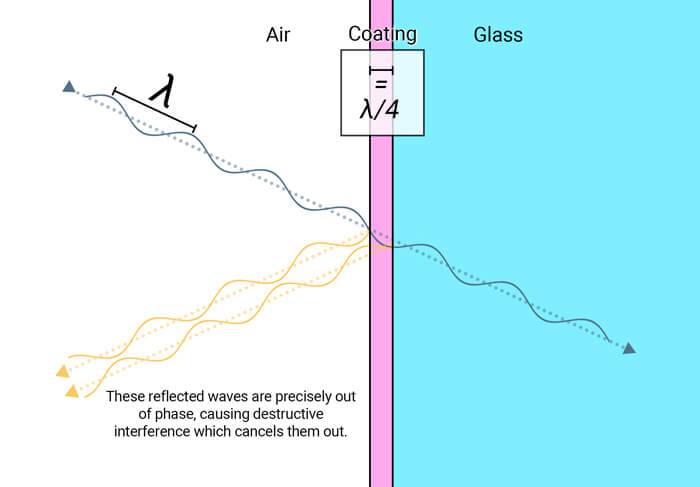

Antireflection coatings can get more efficient by taking advantage of the interference effects described by the wave theory of light to minimize the reflection of a particular set of wavelengths. These coatings induce interference effects by allowing the light to reflect and transmit in ways that would not happen on a bare substrate.

When there is a coating between air and glass, some incident light reflects at the air/coating interface, and some light is transmitted and reflects at the coating/glass interface. The light that is reflected from the coating/glass interface travels twice through the thickness of the coating. When the optical thickness of the coating is equal to a multiple of the wavelength plus a quarter wavelength ((m +¼)λ where m is a whole number), then the light that reflected from the coating/glass interface is offset by half a wavelength from the light that got reflected at the air/coating interface. As a result, due to the destructive interference effect, these light rays cancel each other out and the reflection is minimized.

Antireflection coatings can be improved by adding more layers. The materials and thicknesses used to make a highly efficient optical coating can be modeled with specialized software. Some coatings can have hundreds of layers and can reduce the reflection coefficient to less than 1% at specific wavelengths.

An every-day application of antireflective coatings is on corrective lenses to improve their aesthetics and to reduce the glare that the wearer can see. A more specialized application of an antireflection coating is on solar cells to reduce the reflection losses that reduce efficiency. Other applications include coatings on camera lenses and on some components used for optical experiments with lasers.