Nexdep Physical Vapor Deposition Platform

The Nexdep PVD platform offers a balance between economy and versatility. It can be outfitted with the most robust process enhancements without taking up all the room in your lab or your budget.

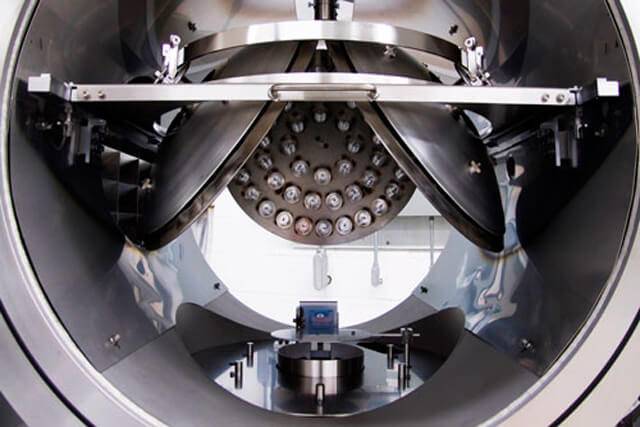

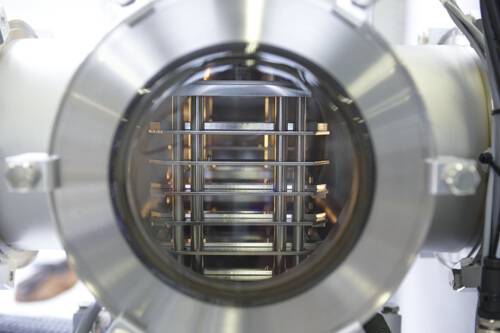

With its 400mm x 400mm baseplate, your Nexdep physical vapor deposition platform can accommodate up to 6 sources, a wide variety of PVD processes, and can be outfitted to achieve ultra-high vacuum (UHV). Your research goals, production demands, and/or application end-goals will inform how to outfit your Nexdep PVD platform. Let’s work together to design the system that will be perfectly suited to your requirements.

A Compact, economical, full featured PVD workhorse

Deposition Source Options

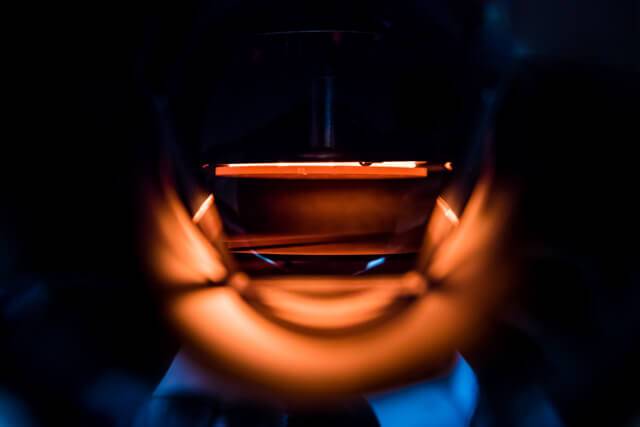

Sputtering

RF, DC, pulsed DC, HIPIMS, and reactive. Circular, linear & cylindrical cathodes are available.

Thermal Evaporation

You can utilize a wide range of boats, filaments & crucible heaters. Auto-tuning ensures precise rate control.

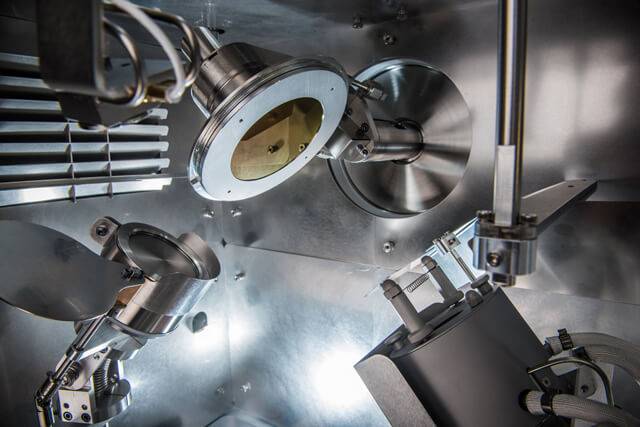

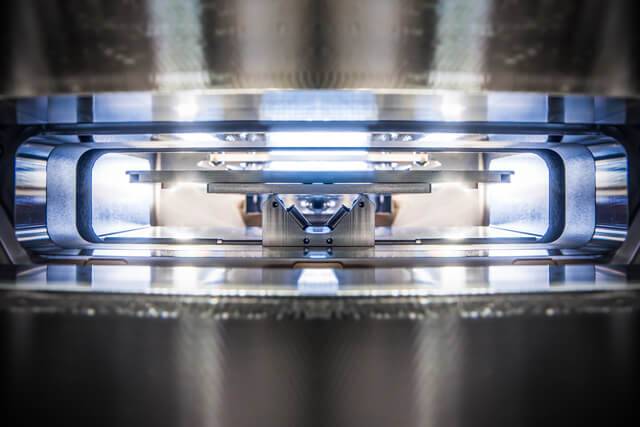

Electron Beam Evaporation

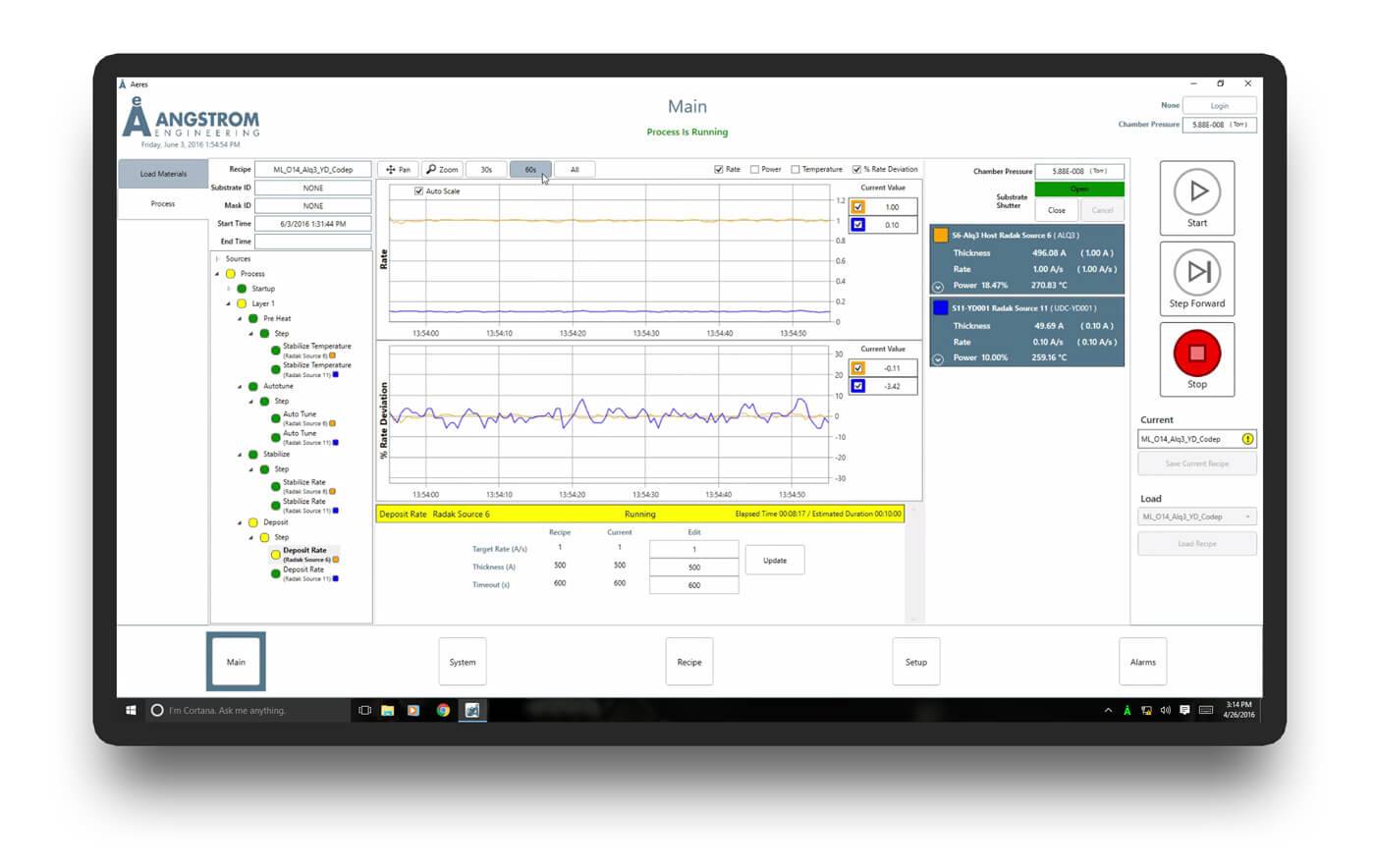

A wide range of source power and power supply options are available. Programmable sweep controller with recipe storage is controlled through Aeres software platform. A torque sensing crucible indexer detects pocket jams. There is room for multiple e-beam sources in the Nexdep chamber.

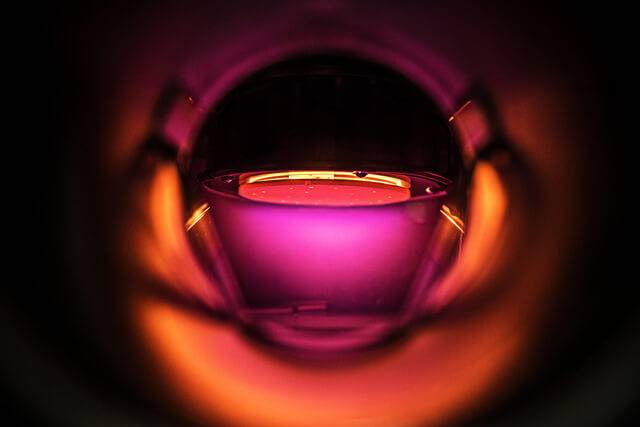

Plasma & Ion Beam Processing

We use a range of ion sources for cleaning and film enhancements, including glow discharge plasma cleaning.

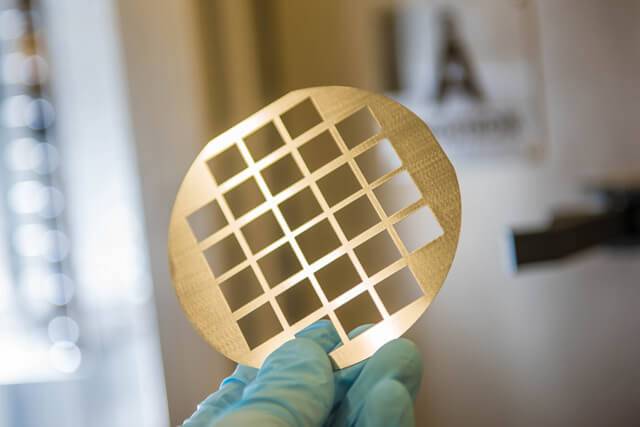

Substrate Fixturing Enhancements

Substrate and Shadow Mask Automation Options

Aeres® Advanced Process Control Software

The two deposition systems we purchased from Angstrom Engineering (EvoVac and NexDep) are being heavily used in our 300-user clean room lab in various research projects and applications. The systems are “workhorses,” highly reliable and user friendly.

Working with Angstrom Engineering has been a pleasure to me and my staff and we are very happy we chose to purchase our deposition systems from your company.

Dr. Nava Ariel-Sternberg – Director of Columbia Nano Initiative Facilities – Columbia University

This video demonstrates capabilities (variable angle substrate tilt and automated transfer) that are available on your Nexdep

Would Nexdep help bring your ideas to life?

Please get in touch and we can collaborate on your project

When we work together, amazing things can happen. Your brilliant ideas with our innovative team will create the tool that will bring your research or production to the next level. We’re looking forward to hearing from you: