Perovskite | Thin Film Deposition for organic photovoltaics

The perovskite family of materials has a lot riding on its shoulders as researchers from all over the world seek to unlock its potential towards a solar energy revolution. Angstrom Engineering can help researchers and market innovators with equipment that brings them closer to their perovskite development goals.

Silicon is still the most popular active material for currently installed photovoltaic systems, but concerns over its environmental impact, its fabrication costs and its scalability have led researchers to seek out alternative high performance materials, such as metal halide perovskites, to harness photonic energy.

The exceptional light absorption and charge transport properties of perovskites have made them an extremely attractive material for solar cell research and development. The power conversion efficiency of perovskite solar cells has increased from 9% in 2012 to over 25% in 2022 (over 31% for perovskite-silicon tandem cells)1, making it the fastest improving solar technology in history.

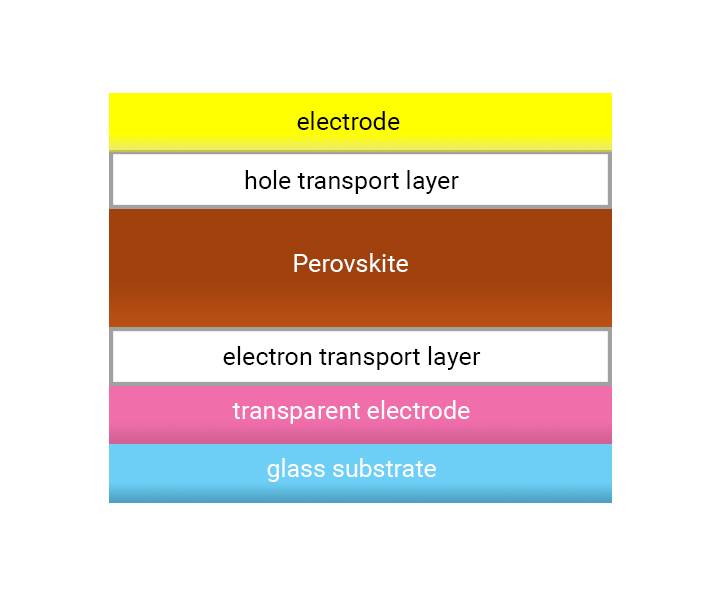

The basic architecture of perovskite-based devices is similar across the field: while there are common material choices for each layer, part of the broad range of perovskite research involves perfecting each of these layers.

Innovating Perovskite Thin Film Devices

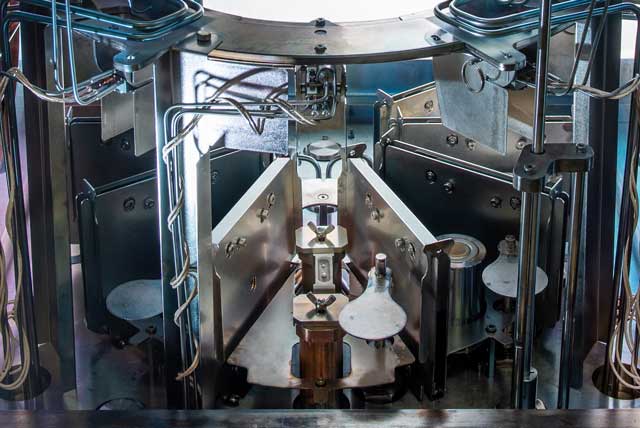

Whether you are approaching perovskites from the research, development, or commercialization perspective, Angstrom Engineering systems are ideal for your work. What follows are key considerations for choosing a system to fabricate your perovskite electronics.

Source Options

Film quality is vital for each layer. Pulsed-DC sputtering provides the best quality films for the transparent electrode, which is most commonly indium tin oxide (ITO). The remaining layers rely on various techniques depending on the end-goal.

Sputtering can be used in the development of photoactive perovskite films with appropriate post-deposition treatment, yielding more intricate control over film quality as well as greater reproducibility. HIPIMS sputtering can be a useful process for perovskite devices, as it allows for reactivity at lower temperatures, reducing damage to films.

Thermal evaporation can be used for the electron transport, perovskite, hole transport, and electrode contact layers. Additionally, your system could also accommodate a ‘bottom-up’ approach where the contact layer is deposited first, and the transparent transmission layers are deposited on top.

We have experience with many groups working in perovskites, and have created systems from small, single-chambered thermal evaporators focusing on the metal contact layer, to multi-chamber robotic clusters that utilize experimental techniques and unique architectures.

Pressure, Gas, & Environmental Control

Every aspect of device fabrication can occur in situ. Layer deposition, reactive processes, spin/dip coating, annealing, characterization, and even encapsulation can occur within controlled environments using connected vacuum and glovebox modules. If your work requires the use of reactive processes, such as the deposition of lead sulfide in the presence of a chemical precursor, the system’s mass flow controller (which is user regulated from Aeres®, Angstrom’s own process control software) allows for exact and precisely repeatable reactive gas control.

Masking Shutter and Stage Heating

Stage heating provides the option for both in situ and post-deposition annealing. Angstrom’s masking shutter provides the ability to partially mask the substrate holder which allows the user to deposit different layers on different substrates within the same run. This feature allows the user to prepare unique samples without breaking vacuum, eliminating the multitude of subtly changed conditions between runs. You can then properly identify the impact of subtle film differences with confidence. Applying all the bling to your stage really is your best chance to efficiently fabricate better performing stacks.

A consultative partnership

We understand you could be approaching perovskite development from a unique angle. Our process specialists will work with you to determine how best to accomplish your development goals.

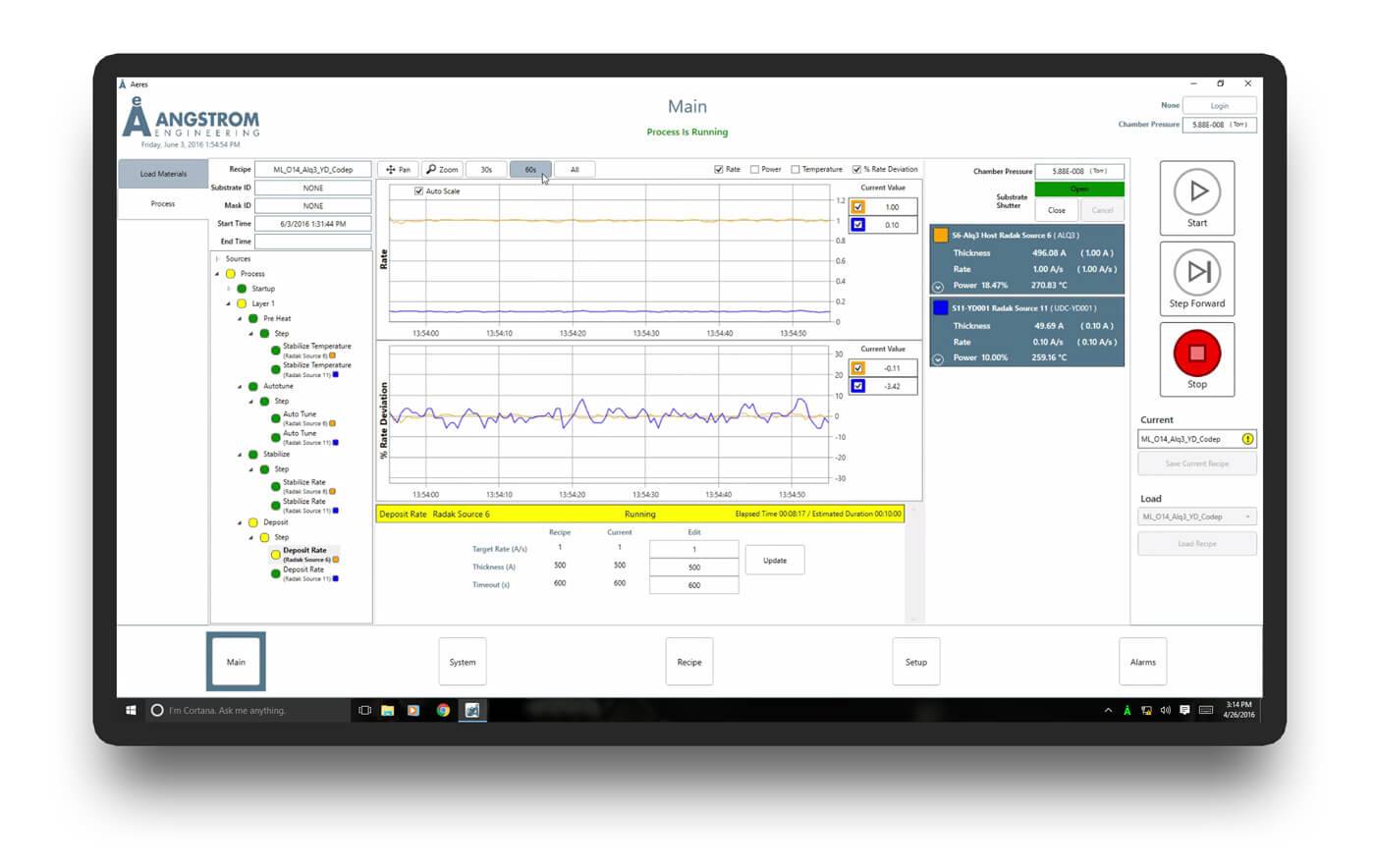

Aeres® Control Software

Every variable in the creation of a high-efficiency perovskite device is critical. For this reason we have integrated explicit control of every step into Aeres®, our advanced process control software. You decide the parameters for every variable, create and edit your own recipes, and then relax, knowing that your process will be executed precisely every time.

Deposition

Our proprietary Auto Tune PID detection algorithm automatically calculates and utilizes process control variables specific to the material, rate, pressure, and stability required for the given evaporation.

Pressure/Gas flow

Fast pumpdowns, precise pressures, and complete control over gas flow for reactive processes. You input values into your recipes, and Aeres® takes care of the logistics.

Stage Rotation / Heat / Masking

Precisely repeatable annealing and rotation values as well as total control of any masking properties.

Clean

The potential for contamination will be far from your mind since every variable is precisely executed, is repeatable, and is then documented for review.

The ease of Aeres®:

create your recipe by entering each variable value.

Press start. Walk away.

The support Angstrom Engineering provides for service issues is exceptional and unparalleled. My job would be significantly easier if I received the customer support Angstrom offers for the other instruments in our facility.

Dr. Ina Martin – Case Western University

WE WANT TO HEAR ABOUT YOUR PROJECTS!

Please get in touch and we can collaborate on your perovskite work.

When we work together, amazing things can happen. Your brilliant ideas with our innovative team will create the tool that will bring your research or production to the next level. We’re looking forward to hearing from you: