Process Enhancement Technologies

Substrate Temperature Control

Improved grain boundary migration, post process annealing, and controlling surface reactions are just a sample of the applications for substrate temperature control. For your heating or cooling applications we have several standard options as well as the ability to customize a solution for your substrate and temperature range.

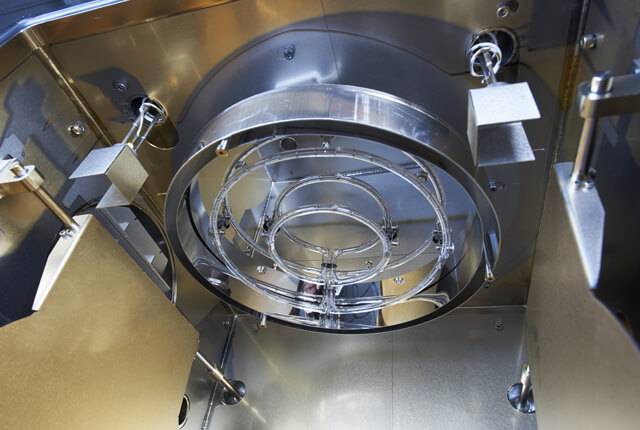

Planetary Motion

Our planetary stage fixturing allows improved uniformity over a large number of substrates. Typically reserved for our Amod and EvoVac lines, planetary fixturing can substantially increase your system throughput.

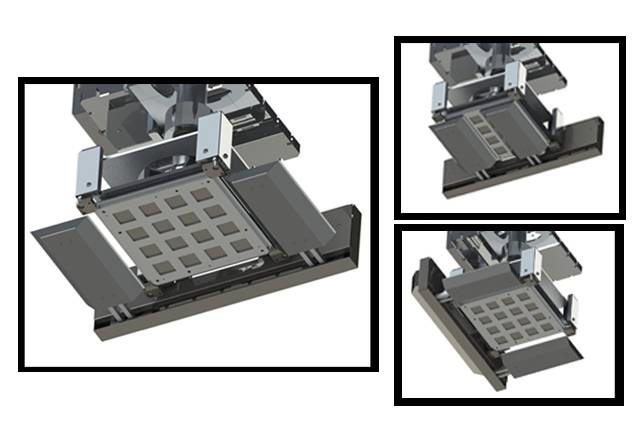

Combinatorial Shutter

Our combinatorial wedge shutter systems provides controlled exposure of single or multiple rows and/or columns within a larger substrate area or within a substrate array. This addition to your stage fixture allows you to perform layer or dopant variations within a single process batch making it an extremely valuable materials & process development tool. Our customers also use this feature to create gradient and stepped film across the substrate. This capability can be added to many of our stage fixtures.

Biasing

If you are looking to control film density or improve adhesion, a bias may be the solution for your process. Angstrom Engineering can configure many of our stages to include a DC or RF bias.

Substrate Cleaning

In situ cleaning via ion beam or glow discharge ensures your substrate is prepared for deposition. For removal of native oxides or residual oils, consider adding a cleaning process to your system.

Our Angstrom system has substantially increased the reproducibility of our organic photovoltaic device fabrication process and overall provides us with a flexible and robust system for the development of new devices.

Dr. Sean Shaheen – University of Colorado at Boulder

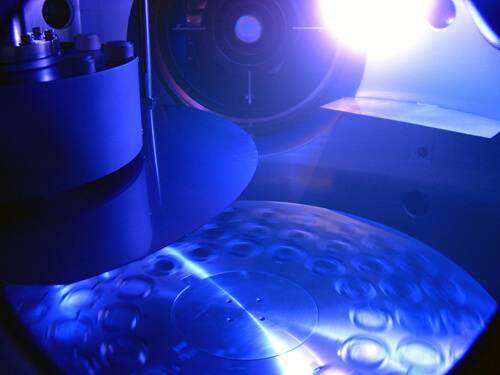

Video: Uniformity Shield

Video: Spinning Substrate

WE WANT TO HEAR ABOUT YOUR PROCESS!

Please get in touch and we can collaborate on your project

When we work together, amazing things can happen. Your brilliant ideas with our innovative team will create the tool that will bring your research or production to the next level. We’re looking forward to hearing from you: