Space & Environmental Simulation

Scientists, researchers, and engineers who design and build the equipment that is used at the various distances above earth require a way to test that equipment while still on the planet's surface.

Angstrom Engineering’s space simulation systems gives those creating technology destined for space, or those studying how low pressure environments affect matter in general, the environment necessary to successfully test and complete their work. They get accurate information on how their components will work under different pressures and temperatures. It is, of course, crucial that all components used in upper atmosphere and outer space environments undergo rigorous testing to ensure they will stand up to the strain of these extreme conditions.

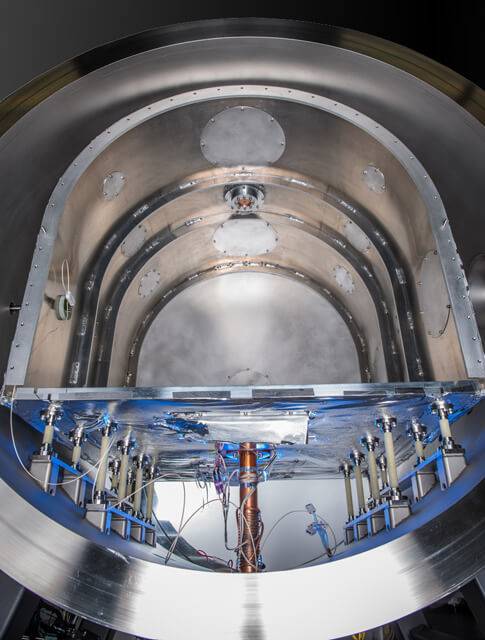

Two of the key elements required to simulate the environment outside of our atmosphere are advanced pressure and temperature controls. To achieve pressure control, Angstrom’s vacuum engineers designed a pressure vessel capable of reaching high vacuum using cryogenic or turbo-molecular pumps in conjunction with a mechanical roughing pump. The temperature control system involves a combination of actively heated and cooled surfaces along with the use of solar selective coatings to absorb excess radiation and remove it from the system. Angstrom has achieved impressive temperature ramping, while also successfully managing to maintain temperature stability within the parameters set out by the user.

The temperature range of the platen depends on the method of heating and cooling, with ranges from LN2 cooled -60ºC with heating up to 150ºC. Our engineers have created a space simulation system with just the right temperature and pressure controls. With the required pumping equipment, thermal control options and data monitoring, our system is one of the most advanced space simulation systems in the market today.

Proven Reliability, Affordable Price

Our vacuum vessels, pumping systems, and fluid circulating systems are all rigorously tested. With one of our space simulation systems, engineers will be able to test components in a high vacuum environment with various options for temperature and pressure controls, all while remaining cost effective.

Angstrom Engineering offers customers the best design and installation of space simulation systems in the field. Our engineers are comfortable with a variety of sizes for your simulation, and can moderate all pressure controls to your requirements.

Powered equipment can be used in the simulator, and other environmental tests can be implemented, such as x-rays, light spectrum emitters, and devices that output various frequencies of EM radiation. Our partners who use our space simulation systems have told us that our systems outperform other simulators on the market and are superior in almost every way, despite being very competitively priced. We are proud that equipment that is being used in space today was tested using Angstrom’s space simulation systems. We guarantee the quality, reliability and safety of our products.

HEADING TO THE FINAL FRONTIER?

Or perhaps you need to simulate alternative pressure and temperature environments?

For affordable space simulation systems for use in laboratories and manufacturing facilities, please get in touch with us today. What technical obstacles can our engineering team help you overcome? Please press the ‘Get in Touch’ button to get in contact with us, we’d be excited to hear about your research and help you in any way we can.